Cite this as: Prust, A. 2024 The Archaeological Legacy of the Lignite Boom in Upper Lusatia, Internet Archaeology 66. https://doi.org/10.11141/ia.66.22

At the beginning of the 19th century, nobody in Upper Lusatia had any idea how much the strange 'black peat' under the heaths and swamps, the forests and ponds, would influence the region, the landscape and, above all, the people in the following 200 years. The discovery of coal seams changed everything. Today, only isolated chimney silhouettes and industrial cathedrals as well as an impressive lake landscape are reminiscent of this time.

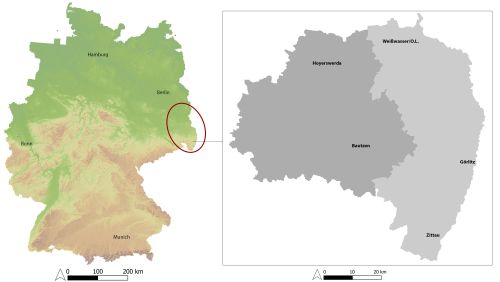

Lusatia emerged from initially two regions during settlement by Slavic tribes in the 6th and 7th centuries: Lower Lusatia, the former area of the Lusici tribe in the northern lowland, and Upper Lusatia, the land of the Milceni in the heath and mountainous area in the south. These days the region covers an area of around 13,000m², stretching across parts of Germany and Poland (Figure 1). Until the 18th century, the West Slavic group of the Sorbs formed the main population. Today, fewer than 60,000 representatives, classified as a national minority, live in the region and keep the traditions and language alive.

For many centuries, agriculture and forestry determined life in Lusatia, until an unprecedented boom in industrialisation at the beginning of the 19th century propelled the region and certain locales to prominence across Europe and the world. The development of the lignite industry with all its side effects was very similar in Upper and Lower Lusatia and made a significant contribution to today's landscape and culture. The four remaining, active opencast mines in both regions still form the 'Lusation lignite mining area' ('Lausitzer Revier').

First reports of earth fires observed near Zittau (Figure 2) in southern Upper Lusatia date back to 1642/3. At the very beginning of the 18th century, well diggers described strong trees, bituminous peat and toxic plumes (Schulz 2005, 8). In 1812, the 'Social-Mineral-Bergwerksgesellschaft zu Olbersdorf' founded the first lignite mine in Upper Lusatia, which developed into a successful industrial company. The raw lignite mined there was spread over the fields as fertiliser (Schulz 2005, 20). Elsewhere lignite was used to pave roads. It was not until 1830 that the people in Upper Lusatia recognised its enormous value as a fuel. Numerous exploratory drillings were undertaken and wealthy landowners, small businesspeople, mostly the owners of brickworks, and private individuals developed one lignite mine after another.

With the increasing conversion to steam engines in small-scale industry from around 1860, the demand for lignite rose rapidly, in cloth manufacture, the glass industry, in brickworks, potteries and breweries. The invention of the briquette press in 1857 by the Bavarian machine builder Heinrich Carl Bernhard Exter further boosted the lignite boom. In 1866, the first briquette factory in Upper Lusatia was founded in Skaska (Schulz 2005, 48). The expansion of the railway lines enabled a supra-regional, profitable export. In the period up to 1919 alone, nine more briquette factories were built in the region, almost all of which continued in production until the 1960s, and some until the 1990s. The Werminghoff briquette factory in Knappenrode, brought into service in 1918 and closed in 1993 (Ring Deutscher Bergingenieure e.V. 2014), is now protected as an industrial monument and is accessible as a museum (Figure 3, left). In a second phase of the lignite boom in the 1960s, three more modern factories were built, one of which (Schwarze Pumpe) is still producing, and is currently the last one in Europe (Figure 3, right).

Until 1885, coal mining was a purely manual operation (Schulz 2005, 62). Either opencast mining or underground mining was undertaken depending on the location of the seam, underground being much more complex and expensive. Pit ponies were initially used, and hand-operated tippers soon gave way to cable railways and ropeways followed by industrial sidings and mine railways. Besides fires and collapsed tunnels and shafts, drainage was the biggest problem, and many of the early pits did eventually flood (Tischer 2017).

By the beginning of the 20th century, large stock companies had already acquired the lucrative coalfields and developed the first large opencast mines in Lusatia. The introduction of electrically operated bucket-wheel excavators increased the output. From around 1925, lignite mining was fully mechanised.

The area-wide energy supply became a central concern of politics and economy and required top-performing lignite-fired power plants. In 1911, the Hirschfelde power plant went on stream with two turbines, each with an output of 1.6 MW. After a rapid expansion and with an output of 25.5 MW, the power plant supplied the entire Upper Lusatia area and parts of Silesia and Bohemia with electricity in 1916 (Franzke et al. 2008, 18). In 1917, two large-scale power plants were commissioned and six more followed in the 1950s and 1960s, which already achieved outputs of 500 MW. Among them was the Boxberg power plant which, after a corresponding expansion with 3520 MW in the early 1980s, was the largest power plant in the GDR and the largest lignite-based power plant in Europe (Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft mbH 2011). Electricity is still generated there today (Figure 4).

After the Second World War and the decoupling from the gas and electricity network of the German Reich, only lignite and a little hard coal provided a basis for the energy supply of the Soviet occupation zone and subsequently the GDR. Lignite mining had absolute priority, especially after large parts of the industrial technology were confiscated and dismantled as reparations - including the complete equipment of 11 opencast mines, 15 briquette factories and a complete power plant (Friedrich-Ebert-Stiftung 1988, 17, 18). Therefore, in the 1950s and 1960s new opencast mines were hastily opened in the Lusatian countryside, followed by another expansion phase in the 1980s.

Lignite is still currently being mined in four opencast mines throughout Lusatia, including the Reichwalde und Nochten opencast mines in Upper Lusatia (Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft mbH 2016) (Figures 2 and 5), the latter being in continuous operation since 1973.

Many other branches of industry also benefited from the lignite boom. A vast number of brickworks in almost every village provided the material for industrial buildings and workmen's dwellings. Foundries as well as plant and mechanical engineering were of essential importance for the equipment of the numerous new factories and to supply the mining and transport companies.

With lignite as an effective fuel and the occurrence of high-quality quartz sands, often quarried as a by-product during coal mining, a glass industry developed that became known far beyond the country's borders. In 1872, the first glassworks were founded in Weißwasser/O.L., a small village in the north-east of Upper Lusatia. In 1903, no fewer than 11 glassworks and dozens of glass processing companies manufactured a wide range of products and exported to large parts of Europe and America (Förderverein 'Glasmuseum Weißwasser' e.V. 2005). By the 1920s, Weißwasser/O.L. was the largest glass-producing location in the world. In the neighbouring municipality of Krauschwitz, known to produce bricks, ceramics and stoneware since the 17th century, a small manufacturer likewise transformed into a world-famous company. The 'Deutsche Ton- und Steinzeugwerke AG Krauschwitz' produced fireproof and acid-resistant containers for the chemical industry (Heinze et al. 2019, 269-82), some with a capacity of up to 6000 litres (Figure 6). Originally founded in 1854 as a small mining company in Großdubrau, north of Bautzen, the 'Margarethenhütte' developed into the world's leading porcelain factory, producing insulators for high-voltage systems since the 1920s (Fleischer 2021) (Figure 6).

An extraordinary production site was established in 1917 in the north-west of Upper Lusatia. Owing to the policy of self-sufficiency, the largest aluminium mill in Europe, the 'Lautawerk', was built in the untouched heathland (Figure 7). While the alumina required was mined about 40km south-west, an in-house power plant guaranteed the energy supply. Therefore, when construction began, the Erika/Laubusch opencast mine was developed between 1914-1917 next to the company grounds, at the time the largest and most modern lignite mine in Lusatia. The factory and power plant went into operation in October 1918, after just 18 months of construction. A new settlement with terrace houses, apartment buildings and a complete social infrastructure such as schools, churches, a hospital, shops, and leisure facilities (Noack 2016, 245-317) was built nearby (Figure 8). This settlement also bore the name 'Lautawerk' and received city rights as 'Lauta' in 1965. The sand-lime bricks used for the construction were manufactured on site in a purpose-built factory.

As early as World War I, an estimated 700-3000 POWs were used in the construction of the aluminium mill, the settlement, and the development of the opencast mine (Belli 2012, 71). More than 17,000 people were employed in the aluminium mill during World War II, again POWs, housed in three barracks near the factory (Belli 2012, 427-577). The Lautawerk was badly damaged by air raids and after the end of the war it was partially expropriated and rebuilt. The factory closed permanently in 1990. Today a waste treatment plant and solar park stand on the site. Only the striking water tower is reminiscent of the largest aluminium smelter in Europe (Figure 15).

Between 1953 and 1974, another gigantic industrial complex was built that surpassed all previous ones: the 'Gaskombinat Schwarze Pumpe'. Four power plants (three being lignite-fired power plants), three briquette factories, a coking plant, one gas plant, water-processing units, its own data centre, the operations centre of the Lusatian mine railway, a works fire service and a works hospital, were all established in the heathland (Figure 9). It was the largest brown coal finishing industry in the world in the 1970s and 1980s and a lighthouse project of Lusatia, the 'energy centre of the GDR' (Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft mbH 2011).

The construction work at Schwarze Pumpe alone employed 14,000 people in 1959 and at the peak of the lignite gasification and mining in the 1980s, more than 15,000 people worked in the various industrial plants (Hübner 2009, 123, 137). Most of them lived with their families in Hoyerswerda-Neustadt (Figure 10), a new district in which more than 22,000 apartments were built between 1955 and 1990 (Biernath 2005). Conveniently, the building works for the industrial complex and the new settlement zone were started on the same day. Both still exist today, but no longer on a reduced scale.

The gigantic industrial cathedrals and numerous workmen's dwellings had to be built, the lignite had to be mined. Right from the beginning, workers were recruited from all parts of the country, but the workforce was never sufficient. So, prisoners were forced to do hard labour as early as 1914. The employment of POWs in the construction and operation of the Lautawerk during World Wars I and II has already been mentioned. Some large enterprises interned forced labourers in their own camps directly on the company premises and satellite camps of concentration camps were set up. The Elsterhorst POW camp (Figure 11), located in the village of Nardt near Hoyerswerda, played a special role in Upper Lusatia. Built in 1938 by order of the Wehrmacht, it could accommodate up to 15,000 people and provided workmen for almost all industrial companies and the private sector in the region (Wirth 2006). It was one of the largest camps for officer prisoners of war (Oflag) in Saxony and certainly unique with the 'University of Hoyerswerda' founded by the internees (Hempel 1999, 14, 15).

Forced labour was by no means an issue only during the world wars. Since the late 1950s, the Schwarze Pumpe industrial complex has had a penal institution with external labour camps, which were also set up next to the large opencast mines. Until the fall of the Berlin Wall, GDR prisoners were forced to work in the lignite industry (Wunschik 2014; Wölbern 2016).

When the political system changed in 1989/1990, the lignite boom in Lusatia also ended. Many industrial facilities were outdated, factories were closed, the demand for lignite decreased and opencast mines were taken out of service. Thousands of people lost their jobs and left the region; factories, infrastructure such as railway lines and entire residential districts were demolished.

The rise and fall of cities can be seen very well in population figures. The village of Weißwasser/O.L. had 631 inhabitants in 1870, two years before the founding of the first glassworks. In 1910, when eleven glassworks in the village and several lignite mines nearby were continuously producing, 11,799 people lived there. The influx of workers was enormous, but city rights were not granted until 1937, when the population was around 14,000. In 1987, the large Nochten and Reichwalde opencast mines and the Boxberg power plant were in operation and 37,388 people inhabited Weißwasser. The urban area had been expanded several times with multi-storey residential buildings. Since most of the industry collapsed, the population has more than halved to date. It was very similar story in Hoyerswerda. In 1955, at the beginning of construction of the industrial complex Schwarze Pumpe and the new district Hoyerswerda-Neustadt, 7755 people lived in the city. In 1981 there were around 72,000 people. Ye today Hoyerswerda has roughly 31,400 inhabitants, including those from the surrounding villages. Numerous other similar examples can be found throughout Lusatia.

The influx of residents whose homes were destroyed for opencast mining also contributed to the increase in the number of inhabitants in the cities. Buchwalde (Figure 12) was the first village in Upper Lusatia to be demolished for opencast mining. Around 350 people had to relocate in 1929 (Förster 2014). In the following few decades, 52 other villages followed a similar fate. In Upper Lusatia alone, thousands of people lost their homes. The last place to meet this fate, Mühlrose, is currently being demolished to make space for the Nochten opencast mine.

Many of these lost villages were once inhabited by Sorbs. There were many reasons why this ethnic group was shrinking, but the lignite industry is a factor through the destruction of villages and communities, and an assimilation process through increased immigration at the beginning of the industrialisation boom. Today, associations and policy try to foster the Sorbian cultural, educational, and scientific institutions and to preserve the traditions and the endangered language.

The loss of work, home and culture was followed by the loss of the landscape. The irreversible effects of more than 150 years of mining require decades of renaturation (Figure 13). There are still plenty of restricted areas as a result of landslides. In addition to agricultural areas, woodlands and nature reserves, the largest, artificial lake district of Europe is being created with a water surface of 14,000 hectares. Navigable canals will connect nine of the twenty-three new lakes and form the 'Lusatian Lake Chain' (Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft mbH 2023). In view of the huge areas and the decades-long restoration, the post-mining landscape should be listed as a UNESCO World Heritage Site and a corresponding initiative has been launched (Institute for Heritage Management 2023).

In August 2020, the law to gradually phase-out coal by the end of 2038 was passed. While many objects from the heyday of early industrialisation have already disappeared, the last remnants of the lignite industry are also in danger of vanishing soon. It is even more important therefore to document these legacies in as much detail as possible and, ideally, to preserve them: the early collieries, the briquette factories, glassworks and brickworks, the foundries, the large open-cast mines, the deserted villages, the huge production facilities, and the forced labour camps. This is quite a challenge for cultural heritage management institutions.

A project financed by the federal government recorded all structural and natural features of the lignite industry in the four lignite mining regions in Germany between July 2021 to September 2023. This project was carried out by the respective federal states' monument authorities, and laid the basis for the preservation and conversion of outstanding industrial buildings and plants into living cultural monuments. The pre- and early industrial workshops and evidence that has already physically disappeared were also documented and mapped, likewise the technical facilities such as briquette presses, turbines, cooling towers, chimneys, glass-melting pots, the large district heating pipes, substations, and rail tracks (Figure 14). Theese elements will be a challenge for future archaeological research as they too represent the industrial history of a region. The project data, roughly 12,000 documented objects in Germany and 1700 in Upper Lusatia, was published in autumn 2023 on the information platform 'KuLaDig'.

But what is worth preserving? All these objects have historical value, most are a rarity - especially the 'superlatives' such as the industrial complex 'Schwarze Pumpe' or the aluminium mill 'Lautawerk'. Hardly anything has survived from the latter (Figure 15). Should this site become an archaeological monument, despite the need for a deep soil remediation and the establishment of new companies and a solar park? Distinctive features of the landscape such as spoil tips or ground subsidence as a result of mining might also be features worthy of protection. The high number of these objects certainly requires a selection.

The public interest in preserving the industrial heritage exists and should be encouraged according to the requirements of the European Convention for the Protection of Archaeological Heritage (Council of Europe 1992). Further research and the transfer of knowledge are also necessary to create a corresponding culture of remembrance and to preserve the identity of the Lusatian people.

Lignite has had a lasting impact on generations of people, the entire region and landscape, and still influences life today. Lusatia was once a sparsely populated region with agriculture and forestry, which developed into the centre of the energy supply for an entire nation and is now on the way to becoming a tourist location with a unique natural landscape. Many people remember the productive years in the second half of the 20th century, but also the enormous losses that came with the political changes and the decline of the lignite industry.

The earlier achievements, both at the beginning of industrialisation and during the boom years, are perceived and appreciated again. People and the region are currently finding their way back to their identity. Now the few remaining testimonies of this epoch must be protected, its history preserved, and knowledge passed on to future generations. The documentation of this heritage can only be seen as a first step.

In Saxony, the State Office for Monument Preservation and the State Office for Archaeology carried out the project to record the structural and natural features of the lignite industry. It was funded by the Minister of State for Culture and the Media.

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.